Learn how top CAE applications running on GPUs are speeding up simulations by 5X or more while lowering costs and energy consumption.

finance-services

Reinvent Manufacturing—From Design to Delivery

Transform Manufacturing From End to End

Harness breakthroughs in design, rendering, simulation, production, remote collaboration, and visualization to revolutionize product development, transform engineering, and power the factory of the future.

Discover How the Manufacturing Industry Is Using AI and Accelerated Computing

Product Development

From conceptual design to marketing asset creation, NVIDIA technology enables designers and engineers to create stunning 3D designs and immersive, real-time, physically accurate visualizations with photorealistic renderings, accelerate design iterations, and bring amazing products to life exactly as envisioned.

NVIDIA Solutions for Product Development

Engineering Simulation

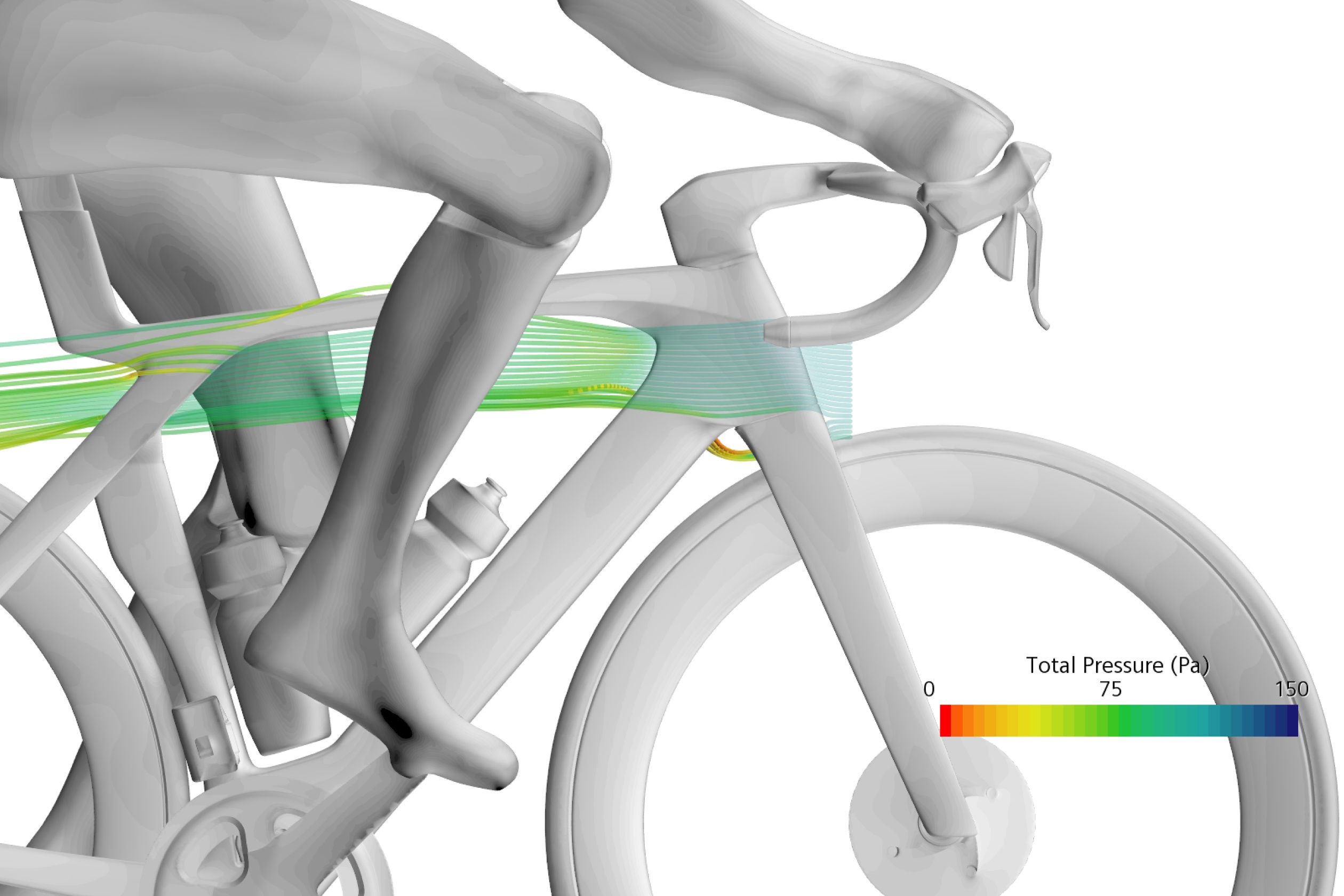

NVIDIA’s GPU acceleration technology provides a wide array of solutions for analyzing and solving complex problems in structural mechanics (FEA), computational fluid dynamics (CFD), computational electromagnetics (CEM) and discrete element modeling (DEM). With NVIDIA, designers, engineers, and simulation experts can rapidly accelerate their CAE workflows and achieve efficient, effective results.

NVIDIA RTX™ for Engineering Simulation

The AI-Enabled Factory

The world’s leading manufacturers are using NVIDIA technology to infuse AI into every aspect of production, delivering higher-quality products and improving profit margins. Industrial digital twins—true-to-reality digital representations of factories—use a combination of AI, physics, real-time data from IoT devices, and insights from maintenance and design records. Digital twin simulations can drive precise factory planning, safety improvements, agility, and flexible factory design. In the physical factory, AI can power automation, robotics systems, quality inspection and testing, and predictive maintenance to eliminate waste from production. Finally, generative AI powered by large language models (LLMs) can support information availability and collaboration to improve operational productivity, equipment upkeep, and issue resolution.

-

Reinventing Maintenance Operations With cuOpt and Jetson Orin

Kawasaki Heavy Industries, Ltd. (Kawasaki) is a manufacturing company that's been building large machinery for more than a hundred years. With NVIDIA cuOpt™ and NVIDIA Jetson™ Orin, Kawasaki partnered with Slalom, Inc. to transform its track maintenance and inspection capabilities.

Reinventing Maintenance Operations With cuOpt and Jetson Orin

Kawasaki Heavy Industries, Ltd. (Kawasaki) is a manufacturing company that's been building large machinery for more than a hundred years. With NVIDIA cuOpt™ and NVIDIA Jetson™ Orin, Kawasaki partnered with Slalom, Inc. to transform its track maintenance and inspection capabilities.

-

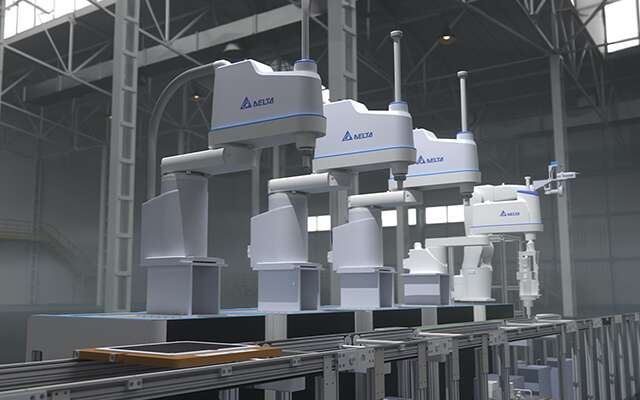

Delta Electronics Is Redefining Production Lines and Industrial Inspection With Digital Twins and Synthetic Data,

Delta Electronics optimizes every part of the factory process before actual production starts using NVIDIA Omniverse™ and the NVIDIA Isaac Sim™ simulation application.

Delta Electronics Is Redefining Production Lines and Industrial Inspection With Digital Twins and Synthetic Data,

Delta Electronics optimizes every part of the factory process before actual production starts using NVIDIA Omniverse™ and the NVIDIA Isaac Sim™ simulation application.

-

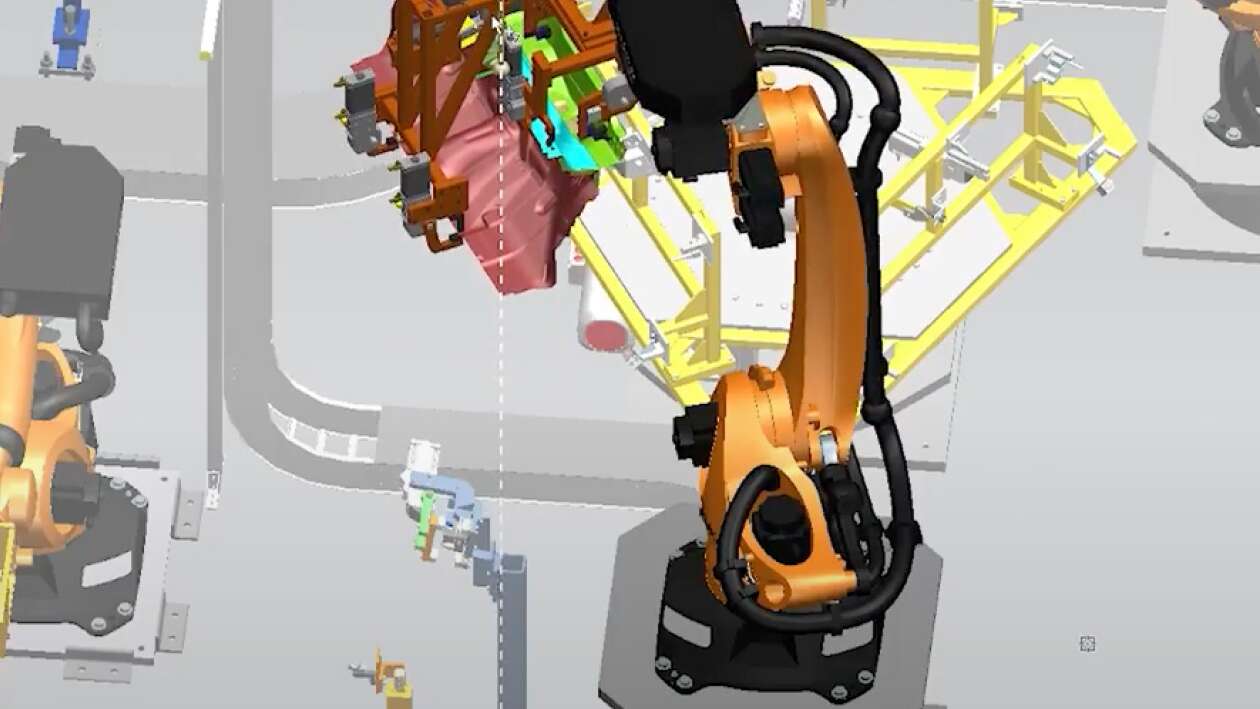

BMW Group Starts Global Rollout of NVIDIA Omniverse

With NVIDIA Omniverse, the automaker is bringing the power of industrial AI to its entire production network as part of its digital transformation.

BMW Group Starts Global Rollout of NVIDIA Omniverse

With NVIDIA Omniverse, the automaker is bringing the power of industrial AI to its entire production network as part of its digital transformation.

Technology

AI and high-performance computing (HPC) hardware, software, and networking solutions for manufacturing.

-

Gain a Competitive Edge With Improved Agility,

HPC and AI enable new levels of collaboration and efficiency in product design, engineering, simulation, and prototyping. Digital twins optimize design and operational flow in factories, warehouses, and distribution centers. Accelerated data science unlocks deeper insights for intelligent forecasting and decision-making. And technician dispatch and vehicle routing can be dynamically optimized to improve efficiency. These reduced operational burdens improve the ease of future expansions and relocations.

Gain a Competitive Edge With Improved Agility,

HPC and AI enable new levels of collaboration and efficiency in product design, engineering, simulation, and prototyping. Digital twins optimize design and operational flow in factories, warehouses, and distribution centers. Accelerated data science unlocks deeper insights for intelligent forecasting and decision-making. And technician dispatch and vehicle routing can be dynamically optimized to improve efficiency. These reduced operational burdens improve the ease of future expansions and relocations.

-

Leverage Automation to Optimize Throughput and Yield,

Automation is creating new levels of speed and accuracy in industrial environments. Robotic systems automate manufacturing, assembly, and material handling. Predictive maintenance and prognostics minimize downtime and maximize the life of equipment. And quality and throughput are increased with computer vision-enabled inspection, productivity inspection, and bottleneck analysis.

Leverage Automation to Optimize Throughput and Yield,

Automation is creating new levels of speed and accuracy in industrial environments. Robotic systems automate manufacturing, assembly, and material handling. Predictive maintenance and prognostics minimize downtime and maximize the life of equipment. And quality and throughput are increased with computer vision-enabled inspection, productivity inspection, and bottleneck analysis.

-

Advance Safety and Sustainability,

Worker safety and waste reduction are important considerations for industrial companies around the world. AI sensors and proactive alerts are being used to enhance functional safety, and digital twins are helping to model and improve worker ergonomics. Machine learning optimizes plant energy consumption, increases farming efficiency, decreases negative environmental impact, and helps develop clean energy systems.

Advance Safety and Sustainability,

Worker safety and waste reduction are important considerations for industrial companies around the world. AI sensors and proactive alerts are being used to enhance functional safety, and digital twins are helping to model and improve worker ergonomics. Machine learning optimizes plant energy consumption, increases farming efficiency, decreases negative environmental impact, and helps develop clean energy systems.

MacBook

MacBook iPad

iPad Apple Watch

Apple Watch Airpods

Airpods iMac

iMac Studio Display

Studio Display iphone

iphone

Gaming Laptop

Gaming Laptop

Gaming Desktop

Gaming Desktop

DDR5 Desktop

DDR5 Desktop DDR5 Laptop

DDR5 Laptop DDR5 Server

DDR5 Server DDR4 Desktop

DDR4 Desktop DDR4 Laptop

DDR4 Laptop DDR4 Server

DDR4 Server DDR3 Desktop

DDR3 Desktop DDR3 Laptop

DDR3 Laptop DDR3 Server

DDR3 Server

Intel Socket

Intel Socket Intel Z890

Intel Z890 Intel B860

Intel B860 Intel B760

Intel B760 Intel H770

Intel H770 Intel B660

Intel B660 Intel H670

Intel H670 Intel H610

Intel H610 Intel Z690

Intel Z690 Intel H510

Intel H510 Intel Z590

Intel Z590 Intel B560

Intel B560 Intel H470

Intel H470 Intel Z490

Intel Z490 Intel H410

Intel H410 Intel B460

Intel B460 Intel H310

Intel H310 Intel B360

Intel B360 Intel B365

Intel B365 Intel X299

Intel X299 Intel Z390

Intel Z390 Intel Z370

Intel Z370 Intel H370

Intel H370 Intel Z270 H270

Intel Z270 H270 Intel B250

Intel B250 Intel Z170 H170

Intel Z170 H170 Intel H110

Intel H110 Intel H81

Intel H81 Intel B85

Intel B85 Intel H61

Intel H61 Intel B150

Intel B150 AMD Socket

AMD Socket AMD B850

AMD B850 AMD B840

AMD B840 AMD TRX50

AMD TRX50 AMD A620

AMD A620 AMD X870

AMD X870 AMD B650

AMD B650 AMD A520

AMD A520 AMD TRX40

AMD TRX40 AMD B550

AMD B550 AMD X570

AMD X570 AMD X470

AMD X470 AMD B450

AMD B450 AMD X370

AMD X370 AMD A320

AMD A320 AMD B350

AMD B350 AMD X399

AMD X399 AMD A88

AMD A88 AMD A68 A78

AMD A68 A78

Cpu Air Coolers

Cpu Air Coolers CPU Liquid Coolers

CPU Liquid Coolers Fans

Fans

AMD CPUs Desktop

AMD CPUs Desktop AMD Server CPU

AMD Server CPU Intel Server CPU

Intel Server CPU Samsung CPUs

Samsung CPUs Other special CPUs

Other special CPUs

Solid State Drives

Solid State Drives NVMe PCIe M.2

NVMe PCIe M.2 SATA 2.5inch

SATA 2.5inch Hard Disk Drive

Hard Disk Drive Server Hard Drives

Server Hard Drives NAS hard drive

NAS hard drive Monitoring hard drive

Monitoring hard drive Portable Solid State Drives

Portable Solid State Drives Memory Cards

Memory Cards USB Flash Drives

USB Flash Drives

Nvidia GPU

Nvidia GPU RTX 50 series

RTX 50 series RTX 30 series

RTX 30 series GTX 16 series

GTX 16 series GTX 10 series

GTX 10 series RX 9000 series

RX 9000 series RX 7000 series

RX 7000 series RX 6000 series

RX 6000 series RX 5000 series

RX 5000 series RX 500 series

RX 500 series RTX 20 series

RTX 20 series

Rack server

Rack server Blade server

Blade server Tower server

Tower server Storage Server Solutions

Storage Server Solutions Network switch

Network switch

Workstation

Workstation Mobile Workstation

Mobile Workstation

Server motherboard

Server motherboard Workstation Motherboard

Workstation Motherboard

PSP3000索尼原装街机掌机-150x150.jpg) SONY Gaming Console

SONY Gaming Console ASUS Gaming Console

ASUS Gaming ConsoleLegion-Go-游戏掌机手持设备-150x150.jpg) Lenovo Gaming Console

Lenovo Gaming Console One XPlayer

One XPlayer日版-Xbox-Series-X-XSX次世代-150x150.jpg) Microsoft Gaming Console

Microsoft Gaming Console XBOX Gaming Console

XBOX Gaming ConsoleMSI-Claw-A1M-050US-游戏掌机-150x150.jpg) MSI Gaming Console

MSI Gaming Console

Motherboard

Motherboard GTX TITAN

GTX TITAN Computer Cases

Computer Cases